NEWS

ANDERTECH at the K-Messe 2022

22.09.2022

WE WELCOME YOU AGAIN TO THE WORLD'S BIGGEST PLASTIC FAIR

Now it's time to visit the K-Messen in Düsseldorf

Here you can see which employees from Andertech Danmark are present at the fair.

We can promise that this time too there will be lots of exciting and interesting news from our suppliers.

From ANDERTECH Denmark participating:

Ken Mark: mobil +45 2023 0649--------------------(19-25 oktober)

Erling Nordtoft -----------------------------------------------(22-25 oktober)

Erik S Andersen --------------------------------------------- (20-25 oktober)

Our experience from previous fairs, tells us that it is extremely sensible to arrange meetings with us well in advance of the fair, if you wish to meet one of our employees.

During the fair, meetings can be arranged by calling our mobile numbers or by calling +45 4915 0400.

If you would like further information please contact us.

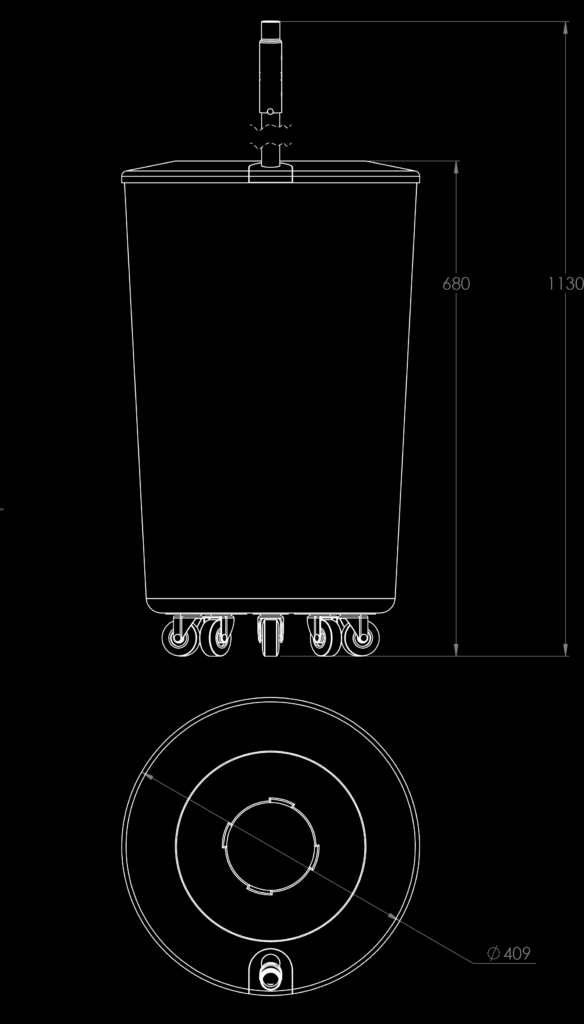

With the ANDERTECH INFO-WORK STAND

you have a perfect and flexible

workstation, with customized fittings .

If you have specific requirements,

the tool suspension items can be customized.

TOOL SUSPENSION ASSORTMENT

1. Small narrow hook - 25 mm

Item: 3D/00062

2. Small hook - 25 mm

Item: 3D/00054

3. Medium hook - 40 mm

Item: 3D/00055

4. Large hook

- 100 mm

Item: 3D/00056

5. Double hook

- U-type,

Item: 3D/00058

6. Sliding tool holder -00x00x00 mm

Item: 3D/00057

7. Ruler holder

- 42x00x00 mm

Item: 3D/000061

8. Screwdriver holder

- with 3 holes

Item: 3D/00059

9. Large storage tray

- 178x80x20mm

Item: 3D/00060

10. Can holder

- 85x885x60mm

Item: 3D/00063

11. Unbraco holder

-

Item: 3D/00064

CONRADT TROLLEY IN STOCK AGAIN