STEN-NEW

OUR PRODUCT family

WEIGHING INTELLIGENCE 4.0

STEN Weighing Intelligence 4.0 – is a completely new

design platform for industrial weighing systems.

Everything (hardware, software, electronics) is proprietary technology created in Humlebaek, Denmark.

The units can work autonomously but are easily integrable as well.

THE ONLY FLOOR SCALE WITH 4 CHANNELS

• Only floor scale with 4 channels (center of gravity display) and IoT as standard!

• Modular

• Precise and easy to operate

• IoT included as standard, also works independently.

• Easy control and operation through a touch color display

IoT

IoT = in this case, means that we have integrated Bluetooth communication as well as WiFi connectivity already in the standard configuration.

We even offer intelligent Cloud services – if you want intelligent data recording and communitations.

Possibilities / options

• Smartphone/tablet app – for bluetooth settings

• Local Web Access

• A-Link connectivity for central overview – same platform that control your raw material handling system.

• Cloud SAAS solution with real-time web access

• Special stainless steel version for outoor use

DIMENSIONS

• Dimensions U-Frame version:

840 x 1,260 x 85 mm

• Dimensions Plate-version: 900 mm x 1.300 mm x 38 mm

+ ramp 248 mm x 900 mm

• 3,000 kg capacity

• Solution +/- 1 kg.

• Other sizes and weighing ranges can be offered on request.

• Special stainless steel version for outoor use

DIMENSIONS

• 840 x 1,260 x 85 mm

• 3,000 kg capacity

• Solution +/- 1 kg.

• Other sizes and weighing ranges

can be offered on request

• 3,000 kg capacity

• Solution +/- 1 kg.

• Other sizes and weighing ranges

can be offered on request

TOUCHSCREEN EXAMPLES

Easy navigation on the touchscreen

EASY TO MOVE

Easy to move around, due to the stable built-in wheels.

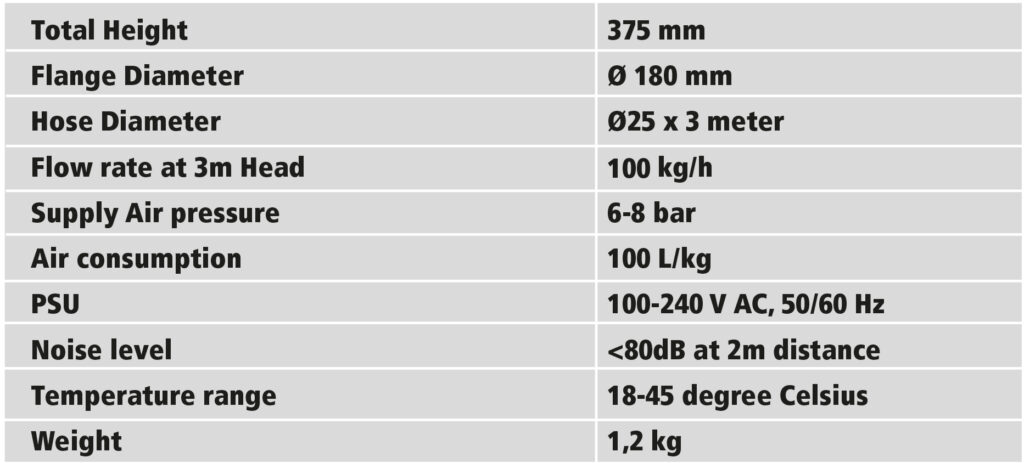

CONRADT HOPPER LOADER

COMPACT - LIGHT - AFFORDABLE

ANDERTECH A/S has developed a new type of hopper loader that makes handling of plastics granules easy.

Conradt

The 3D printed CONRADT is smaller, lighter and cheaper – compared to other loaders – and will save resources as well expenses.

The conveyor

Working on the venturi principle, is specifically

developed for the conveying of MasterBatches and other free

flowing plastic granules in smaller amounts.

As the loader does not create airpressure i the machine/dosing hopper, it is suitable for use on sensitive weighing/dosing

systems.

For specific critical and sensitive cases, CONRADT has (as standard

feature) input socket for an suction allowance signal given by

the gravimetric blender.

All the CONRADTS are produced on our own 3D printfarm in

Humlebaek, north of Copenhagen.

We have

reach full capacity and supply Globally through autohorized

distributors.

The electronic control, also developed in-house, is very logical,

easy to understand and easily operated.

Your can adjust conveying/suction time and the number of faulty loadings before

the alarm will be set.

CONRADT has a very bright LED indicator

ring signalling actual status and helping do the programming of

parameters.

Power is connected by a CAT6 cable.

CONRADT is prepared for Industry 4.0 and can be

supplied in a special version ready to integrate into central

control systems.

CONRADT has a weight

of only 1.200 grames

and is supplied ready to

operate including 3 meters of conveying hose,

stainless suction pipe, 2

hose clamps, mounting

flange with selflocking

bajonet connection,

power supply and

cable.

Play Video

Conradt is supplied ready to operate including :

• 3 meters of conveying hose

• Stainless suction pipe

• 2 hose clamps

• Mounting flange with selflocking bajonet connection

• Power supply

• Cable

Color change in just...

...60 seconds!

The brand new innovative and flexible CONRADT TROLLEY TM allows fast and accurate color changes to be made in just 60 seconds...

... without wasting even a single granule !

Few steps:

1. Position the next production color

Trolley-Unit next to the present one

2. Close valve below CONRADT Loader in use

3. Unplug compressed air and 24V power

4. Moove the CONRADT unit including hopper and hose onto the

CONRADT TROLLEY TM

5. Take the dosing screw unit from the machine and empty it into the CONRADT TROLLEY TM

6. Position the next color CONRADT

onto the dosing unit and open valve

7. Plug in air and 24V and RUN…

3D-PRINT

From your file - to your product - in next to no time

Harvest the advantages of AM technology, giving you flexibility in your design process and minimizing turnaround time. You will be able to, without consequences, change and optimize your product as it evolves through market feedback and customer reviews. No longer will you be limited by tooling costs and manufacturing limitations such as shape and tool access

HIGH VOLUME 3D PRINT

We have 60 3D printers, and growing, ready to mass produce your items.

220mm x 220mm x 220mm

LARGE SIZE 3D PRINT

In a new department we 3D print up to

1.250mm x 600mm x 700mm

3D PRINT KNOW HOW

Our engineers are ready to help you with ADM product optimization and ensure that your 3D product requirements are met.

3D PRINT DESIGN

Don’t be limited by conventional manufacturing methods. Rethink your product to take advantage of ADM technology.

3D PRINT PRODUCTION

We can produce a wide range of products with extremely flexible 3D production sizes. No tooling and minimal setup costs.

COMPETITIVE 3D PRINT PRICES

Get a quote now on 1 - 10 - 100 - 1000 pcs.

3D-Printfarm.dk

ADM-Factory.dk

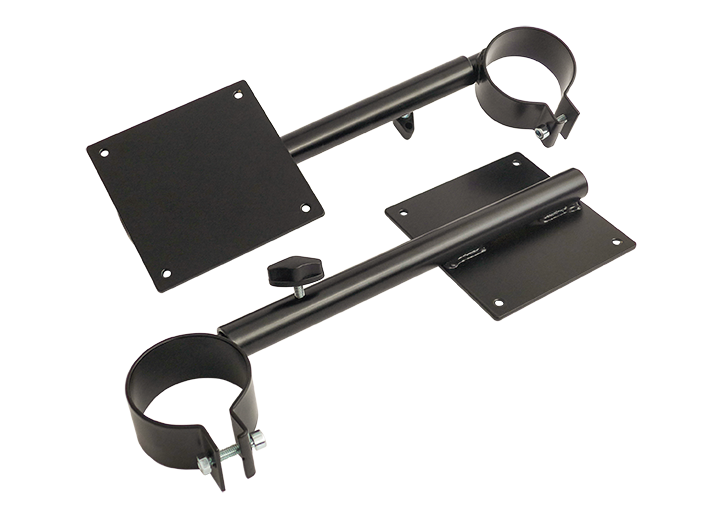

Versatile, strong and flexible INFOstand for your production cells.

With the ANDERTECH INFO-WORK STAND you have a perfect and flexible workstation, customized fittings as you need

Tool Suspension Assortment